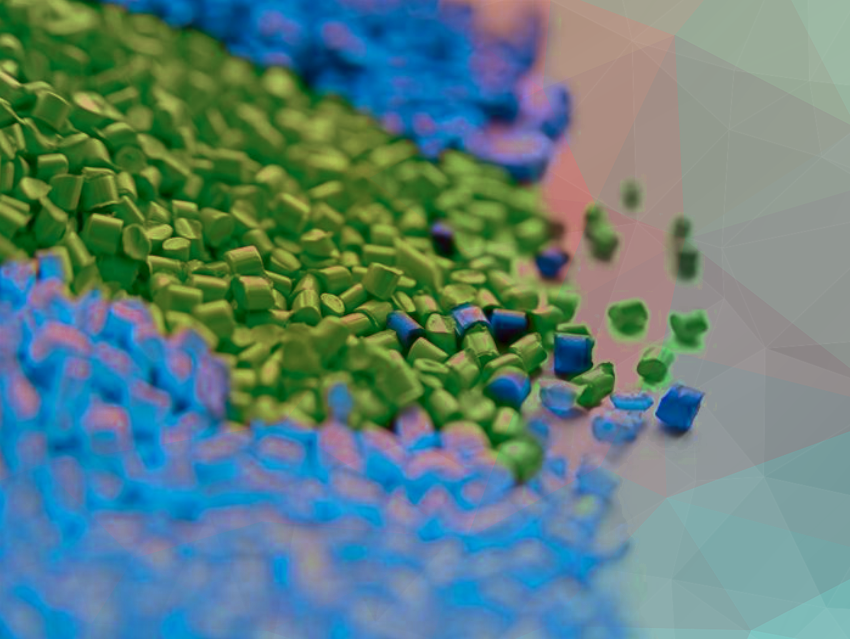

Neste and Lotte Chemical have joined forces to improve the sustainability of chemicals and plastics by replacing fossil resources with renewable ones. Neste will supply Lotte Chemical with Neste RE™, a raw material made entirely from renewable sources, for the production of a wide range of plastics and chemicals at Lotte Chemical’s facilities in Korea. These sustainable products can be used in various sectors such as packaging, construction, textiles, and electronics.

Fossil feedstocks can be replaced with Neste RE without infrastructure changes. Plastics made from Neste RE are of the same quality as those made from conventional feedstock. According to Neste, the use of renewable Neste RE reduces greenhouse gas (GHG) emissions by more than 85 % when replacing fossil raw materials, and the use of recycled Neste RE reduces GHG emissions by about 40 % when compared to feedstock production from fossil materials and incineration of plastic waste.

In December 2023, Neste joined forces with Eppendorf, Hamburg, Germany, to advance the development of laboratory products made from renewable raw materials.

Neste refines waste, residues, and other raw materials into renewable fuels and sustainable raw materials for plastics and other materials. The company produces renewable products at its refineries in Finland, the Netherlands, and Singapore with a current annual nameplate capacity of approximately 3.3 million tons. The company’s goal is to make the Porvoo oil refinery in Finland the most sustainable refinery in Europe by 2030. Neste is committed to achieving carbon-neutral production by 2035 and to reducing the carbon emission intensity of products sold by 50 % by 2040.

- Neste Oyj, Espoo, Finland

- Lotte Chemical, South Korea