Against the backdrop of surging transition metal demand and mounting environmental challenges from mining and waste disposal, metal recycling from spent catalysts and e-waste has emerged as a global priority. Projections show that global copper mining demand from 2020 to 2100 will hit 8.7 billion tons, dwarfing the 2 billion tons of proven reserves. Metal recycling offers a dual solution, bridging resource shortfalls while curbing ecological harm, and is now a linchpin for sustainable resource management and environmental conservation.

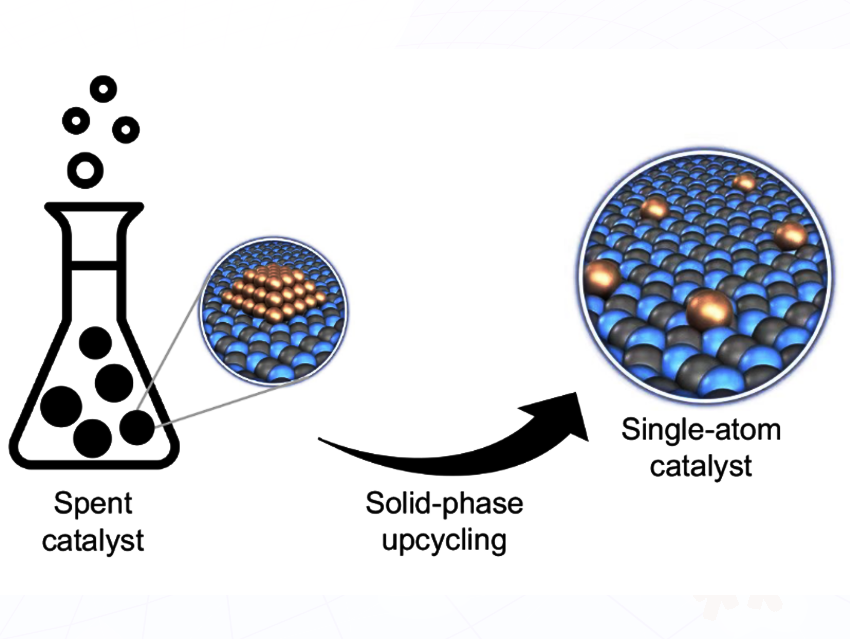

Zhongxin Chen, The Chinese University of Hong Kong, Shenzhen, China, and colleagues reported a solid-phase upcycling method for producing ultrahigh-loading single atom catalysts (SACs) from spent catalysts. Guided by artificial intelligence (AI)-driven big data analysis, the researchers identified a critical gap in the sustainable recovery of early transition metals.

The innovative approach entails using heat to redisperse metal aggregates into single atoms on a polycrystalline carbon nitride (PCN) support. This process yields highly active M1-PCN SACs (M = Fe, Co, Ni, Cu), with metal loadings reaching up to 20 wt% for copper. A subsequent techno-economic analysis reveals that this method slashes production costs and greenhouse gas emissions by two-thirds, compared to traditional hydrometallurgical and pyrometallurgical processes.

This breakthrough not only fills a key research gap but also charts a new course for sustainable metal recovery technologies, promising significant advancements in the field.

- Solid-Phase Upcycling Toward the Production of Ultrahigh-Loading Single-Atom Catalysts

Guanwu Lian, Zefan Du, Yifan Wang, Yelan Xiao, Mengyao Su, Chao Wu, Yucong Huang, Yuansheng Lin, Jingjing Xiong, Yichen Chen, Shibo Xi, Wenguang Tu, Zhigang Zou*, Zhongxin Chen

Aggregate 2025

https://doi.org/10.1002/agt2.70052