Plastics are used for many applications in everyday life. Due to their high stability, plastics are generally difficult to degrade in Nature. They are stored in landfills, incinerated, or often improperly disposed of, leading to widespread pollution. Additionally, the preparation of plastics from fossil resources requires energy-demanding refining steps. Mechanical recycling is a common method for the reuse of plastic waste, but often leads to materials of lower quality. Chemical recycling, which converts waste plastic back to valuable raw materials, is an emerging strategy with the potential to reuse plastic waste and reduce the dependence on fossil resources.

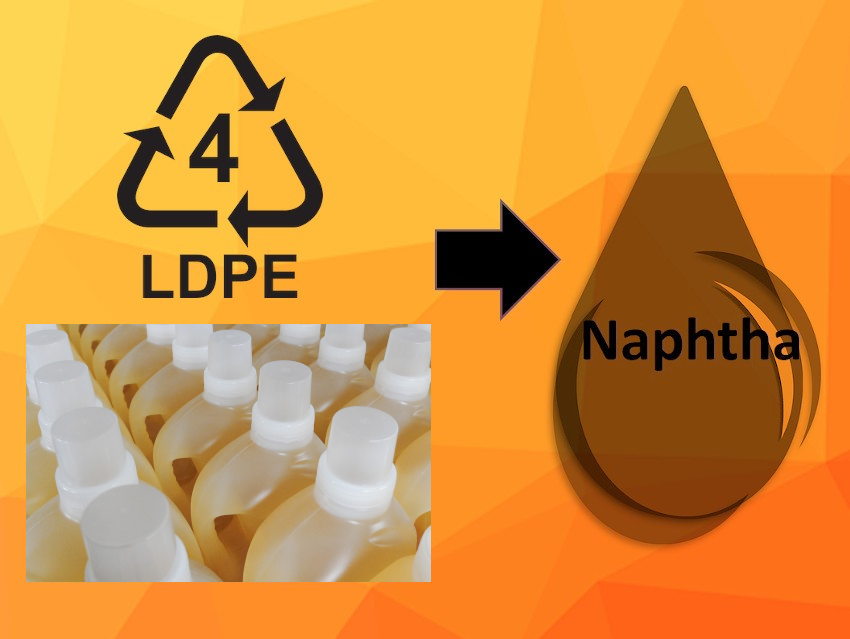

Hu Luo, Hui Wang, Shanghai Advanced Research Institute, Chinese Academy of Sciences, and colleagues have developed a method for the conversion of waste low-density polyethylene (LDPE) to naphtha (C5–C9 hydrocarbons) over a catalyst that combines ß-zeolite with platin nanoparticles immobilized in the channels of silicalite-1 (S-1) zeolite. Using this catalyst mixture, the team transformed LDPE to naphtha in 89.5 % yield with over 95 % selectivity towards the desired C5–C9 carbon products at 250 °C under 3 MPa of hydrogen.

The macromolecules are cracked on the acid sites of the ß-zeolite to form olefinic intermediates, which then diffuse into the channels of the silicalite where they are hydrogenated by the platinum nanoparticles. Due to the confinement of the active metal sites, high size selectivity is achieved. The catalyst was successfully regenerated four times.

The researchers proposed a concept for upscaling the process to an industrial plant and performed a simulation-based energy assessment and life-cycle analysis of the method’s carbon footprint. They calculated a reduction in energy use of 15 % and 30 % reduced greenhouse gas emissions. Thus, the method could contribute to the reduction of CO2 emissions and plastic waste.

- Converting Plastic Wastes to Naphtha for Closing the Plastic Loop,

Lin Li, Hu Luo, Zilong Shao, Haozhi Zhou, Junwen Lu, Junjun Chen, Chaojie Huang, Shunan Zhang, Xiaofang Liu, Lin Xia, Jiong Li, Hui Wang, Yuhan Sun,

J. Am. Chem. Soc. 2023.

https://doi.org/10.1021/jacs.2c11407