Realizing practical rechargeable Mg batteries (RMBs) requires thin magnesium foils. The thickness of the metal anodes strongly influences the practical energy density of batteries with metals as anode active materials. However, the preparation of thin magnesium foils for application in MRBs is hampered by the brittleness and limited workability of magnesium.

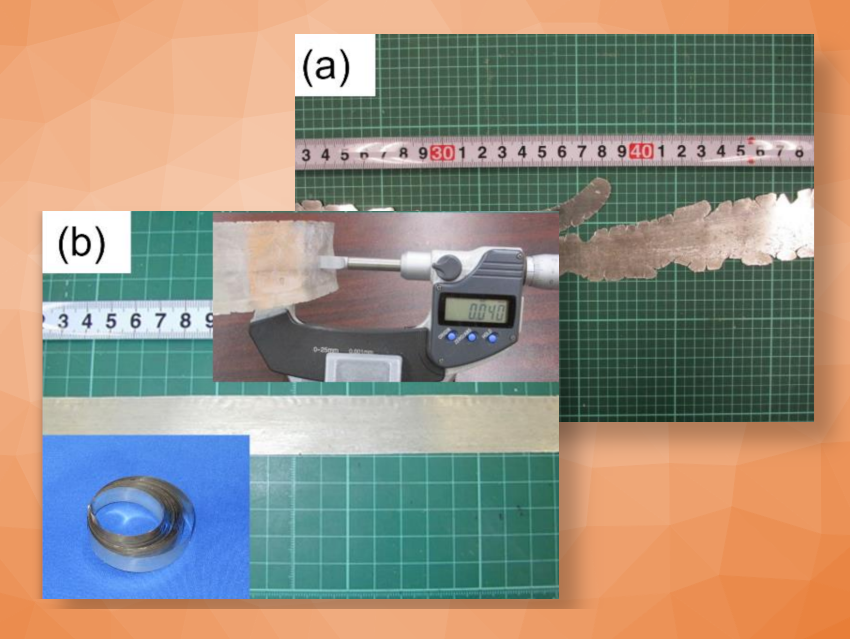

Toshihiko Mandai and Hidetoshi Somekawa, National Institute for Materials Science (NIMS), Ibaraki, Japan, have developed ultrathin Mg metal foils for RMB applications. The team fabricated ultrathin magnesium foils with thicknesses below 45 μm, fine grains, and no residual stress. They achieved this by controlling the initial microstructures of the Mg billet and the conditions during rolling, a process in which the metal is pressed between pairs of rolls to reduce the thickness.

The researchers started from commercially cast pure Mg, which has an average grain size of over 100 μm, and extruded it at 423 K to refine its grain structures. The fine-grained extruded Mg was rolled at 573 K to a thickness of ca. 0.5 mm and then rolled again at ca. 573 K. Rolling at relatively high temperatures decreased the residual stress in the material.

The resulting foils exhibited excellent electrochemical characteristics as an anode for RMBs. The team used the warm-rolled magnesium foil combined with an α-MnO2 cathode to assemble laminate-type cells. This work could be a step towards realizing high-energy-density RMBs.

- Ultrathin Magnesium Metal Anode – An Essential Component for High‐Energy‐Density Magnesium Battery Materialization,

Toshihiko Mandai, Hidetoshi Somekawa,

Batteries Supercaps 2022.

https://doi.org/10.1002/batt.202200153