Research and production in a digital world was this year’s general theme of the ProcessNet Conference and the 33rd DECHEMA Annual Meeting of Biotechnologists. Approx. 1,000 chemical engineers and biotechnologists met in Aachen, Germany, for 34 keynote and tandem lectures, 304 scientific lectures, poster sessions, a program organized by the kjVIs (creative young process engineers), an exhibition, as well as many networking opportunities and additional activities. The 13th ChemCar competition, for example, was a highlight of the conference. The latest idea of the kjVIs, the ChemPlant competition, took place for the first time.

Living on the Moon

Traditionally, this most important national meeting for chemical engineers and biotechnologists starts with a look beyond the horizon. This year, Dr.-Ing. Matthias Maurer, a European Space Agency (ESA) astronaut and materials scientist, gave insights into the life of an astronaut at the International Space Station (ISS) and into future space projects. Since November 2000, the space station is permanently inhabited by astronauts. The ISS is about the size of a soccer field. It revolves around the earth at about 400 km altitude within about 90 minutes. Astronauts who live and work on the station experience 16 sunrise and sunset times each day.

One reason to fly into space is to do experiments in zero gravity. On Earth, such experiments can be done in the Zarm drop tower in Bremen, Germany. However, the time for the experiment is only a few seconds. Parabolic flights allow for 20-second experiments. On the ISS experiments of eight months up to years are possible and also commercial weightlessness experiments in an experimental cube are now possible. Companies or research teams can develop their own experiment inside a cube. Together with other cubes, it will be brought to the ISS and will be installed in the so-called ICE Cubes Facility. When it is time to start the experiment, the ICE Cubes Mission Control Centre will activate and pass on control to the owner of the cube experiment so they can run their experiment according to their predefined operations plan and directly monitor and control the experiment.

In the future, the operation of the ISS might be entirely commercial. NASA and other space agencies might be preparing for lunar and Mars flights, instead. The space agencies of different states are considering a kind of space station in the lunar orbit. Deep Space Gateway would serve as a springboard for flights to Mars. Here, astronauts will test equipment and methods such as the coupling of modules, the assembly of larger spaceships, and a long stay in space. In addition, it might be possible to service the satellites that are in geostationary orbit and eventually cannot operate anymore because their fuel ran out. It is more efficient to do this on the Moon because of the different gravitational potential of the Moon and Earth.

The Moon is much further away than the ISS. It takes a much greater effort to get there and provide astronauts with transport flights. To bring as little material as possible to the moon, several ideas are tested: The lunar rock consists to a large extent of oxides, such as sicilium, iron or magnesium oxide. Oxygen could thus be obtained by pyrolysis using sunlight concentrated at one point.

Bricks could be sintered from Moon sand to build a Moon base to protect astronauts and equipment against micrometeorites and radiation. A microwave 3D-printed base constructed by taking solar energy and dust from the ground and baking it to directly construct any shape wanted. Due to the unique properties of the lunar soil and the absence of an atmosphere, microwave sintering can create a solid building material similar to ceramics.

New protective suits for astronauts are needed which can withstand the aggressive Moon sand. The Moon sand is very angular, such a kind of sand does not exist on Earth. The Moon sand sits in the seals of the suits. The Apollo astronauts had the problem that some of the seals were no longer 100 % reliable after only two to three Lunar walks. However, a suit must survive the entire duration of the mission, even if it lasts half a year. Suitable materials and processes have to be found.

Matthias Maurer ended his inspiring talk with the notion that if we want to go further and further into space, a permanent outpost on the Moon will be a major advantage. In addition, cooperation with additional partners like China, the Arab Emirates, Korea, India is needed.

Figure 1. Matthias Maurer during his talk. Pictures © Wiley-VCH/WSieß

Selected Talks

Times are Changing

The digital age is increasingly shaping our everyday lives. The impact of digital transformation is more than a simple fourth industrial revolution. Professor Martin Stratmann, Max Planck Society for the Advancement of Science e.V., Munich, Germany, speaks of an era change.

Science plays an extraordinary role in this era change, as it has in the past. The nucleus of the turn of the century is the enormously increased computing power, the enormous ability to exchange data, i.e., the network performance, as well as the large amount of data that is generated and evaluated.

In addition, today we live in a time where human beings are changing the globe as never before due to their technology. Global warming is just one example. The politics must react. But it cannot react as it did in the past with short-term thinking – you cannot switch off global warming in two years. But what will happen in 10, 50, 100, 500 years? What basis will our planet offer for us to live? The answers to these questions can only come from model calculations, from science. And suddenly politics is limited in its field of action. Science is not only relevant as a guide but as a limiting factor on the political field of action. And conversely, of course, it is clear that politics has other requirements for science. Politics does not want to enact a policy that turns out to be wrong because science came up with false predictions.

Hence, we live in a time that Martin Stratmann describes as a balancing act. There is, on the one hand, society’s expectation of science communication: hard information, timely information, showing risks and opportunities. On the other hand, there is a science world that is increasingly divided with experts who have a technical notion that is hard to understand if you are not from the same field. It is incredibly difficult to combine these two things and, of course, there is a lot of mistrust.

Why does the population have problems with science? For one thing, there is too much going on. CRISPR/Cas comes to the table today, tomorrow you know it can have a huge impact on our lives, but no one really understands what CRISPR/Cas is. It is not possible to react so quickly to how scientific news after news is put out into the world. Then, we publish too much, Martin Stratmann says. We should come back to fewer and more relevant publications. We publish so much that you cannot tell anymore, what is good quality, what is bad quality. In addition, we have an education problem. Basically, the general public does not know what science is doing.

At the same time, the methodological approaches of communication are changing. Classically, we have always had something like a gateway; newspapers such as the FAZ offered a quality journalism that differentiated between what is really important and what is less important. This model is running out. Completely new communication systems are created instead.

The science organizations, including the Max Planck Society, must and are in the midst of changing their communication behavior. We have to communicate directly, become a broadcaster, get involved in new media, improve the ability to express ourselves in public. And we see that the population eagerly picks this up.

This era in which we live and which is science controlled has enormous opportunities, but it also creates fear of loss. In this balancing act, science must be able to communicate, must speak out, must come into contact with society. Martin Stratmann hopes that in the end the conspiracy theorists will not prevail and take up the space that science actually needs to be able to develop freely.

How to Stop Employees from Fearing Digitalization?

For several years, Linde AG, Munich, Germany, has been testing new ideas with a limited budget in two Digital Base Camps in Munich, Germany, and Singapore. The Base Camps are staffed with digital experts from inside and outside the company and supplemented by external start-up networks. In a maximum of three months, a proof of concept must be ready, then the scaling follows in the business area of Linde. Everything that is not finished in three months will be closed. The teams focus exclusively at customer benefits and question everything else. The idea is to take what is there and to see how daily work is changing and to create the fastest possible sense of achievement.

Dr. Christian Bruch, Linde AG, warns that in Germany we always start from threat scenarios and from the negative side. Jobs are taken away, we are digitally threatened, etc. In Asia, he experiences that employees say “Great, I want to try this, so I can qualify to do something different”. Bruch wishes to see a hunger for learning and a pleasure in change again in Germany. Germany is a country that has developed, tried, and made many things. Even here, people have failed. In our current situation, of course, we also want to protect what we have achieved. However, our jobs will change and if we do not deal with this then we will not be able to understand what we could do, he says. We will then not have the tools to prepare for the future.

News in Search for Antibiotics

“We got a bit too used to antibiotics working.” The antibiotics we use are almost all from the 50s and 60s of the last century. Current antibiotics belong only to few classes and the number of cellular targets is limited. Particularly against gram-negative germs, therapeutic approaches are missing. Very few new antibiotics are in the development pipeline. Substances with new mechanisms of action are in demand. Unfortunately, the industry is doing very little here. Professor Rolf Müller, Helmholtz-Institute for Pharmaceutical Research Saarland (HIPS), Saarbrücken, Germany, says, we need academic institutions that are involved in this huge problem so that we will again see a new antibiotic with anti-gram-negative activity.

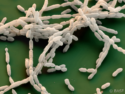

Rolf Müller and his team primarily focus on the discovery of microbial natural products to develop new antibiotics. The soil-borne microorganisms myxobacteria, for example, produce a broad range of anti-infectives that contain novel scaffolds and show promising bioactivities [1]. Some act against tumor cells, such as epothilone, which has already been developed into a cancer drug. Some—including myxopyronine, corallopyronine and ripostatin—can kill other bacteria. Their mechanism of action differs from all other previously known antibiotics. The substances work very well against bacteria in the culture dish. However, to be able to develop this effect in the human body and also to be compatible with patients, they would first have to be developed into medicines.

Figure 2. During their talks from left to right: Dr. Christian Bruch, Linde AG, Munich, Germany, Professor Rolf Müller, Helmholtz-Institute for Pharmaceutical Research Saarland (HIPS), Saarbrücken, Germany, and Professor Martin Stratmann, Max Planck Society for the Advancement of Science e.V., Munich, Germany. Pictures © Wiley-VCH/VK

1st CIT Lecture

The journal Chemie Ingenieur Technik (CIT) publishes its 90th volume this year. CIT is owned by the German Chemical Society (GDCh) and is associated with DECHEMA and VDI-GVC (Association of German Engineers and Society for Chemical Engineering). It is a host for publications in chemical engineering and industrial chemistry bridging the gap between fundamental science and applications.

CIT was created as part B of the Zeitschrift für angewandte Chemie of the Association of German Chemists. Under the title Die chemische Fabrik (The Chemical Factory) it became an independent journal in 1928. DECHEMA provided it as a membership magazine. The first editor was Max Buchner, the organizer of the first ACHEMA in 1920. In 1942, the title of the journal was temporarily changed in Die Chemische Technik (The Chemical Engineering) and after a forced break to build up after the World War in 1946, the journal first appeared again as a part of Angewandte Chemie in 1947. In 1949, the journal received its current title Chemie Ingenieur Technik or CIT for short.

Digitialization of the Process Industry

The CIT Lecture continued with digitization, this time with the challenges and opportunities for the process industry. In April 2018, a top-class symposium in Tutzing, Germany, discussed the challenges, chances, and opportunities of digitization in the process industry over three days and prepared twelve theses which will be further discussed in a temporary working group.

Professor Norbert Kockmann, TU Dortmund, Germany, one of the leaders of the Tutzing symposium, summarized that lean processes are the essential basis of the internal processes on which digital tools such as data analysis, networking, and communication can be based. Digitalization opens up new possibilities, changes the rules of the game and connects people and disciplines through platform solutions and networking, through digital twins (digital replica of physical assets, processes, and systems) and simulations, as well as through artificial intelligence and data integration [2].

Following Lao-tse, Norbert Kockmann concluded: “A journey of 1000 miles begins with a single step. If we have a vision, if we have goals, we will not reach them in a few steps, but we have to take many steps. We are now celebrating 90 years of CIT. In ten years, CIT will be 100 – I am curious what we can report then.”

Figure 3. 1st CIT Lecture. (left to right) Dr. Ljuba A. Woppowa, CEO of the VDI-GVC, Dr. Barbara Böck, Editor-in-Chief Chemie Ingenieur Technik (CIT), Professor Norbert Kockmann, TU Dortmund, Professor Kurt Wagemann, Executive Director of DECHEMA. Pictures © Wiley-VCH/VK

|

The 12 Tutzing Theses on Digitalization in the Process Industry |

Figure 4. During a break and at the conference dinner “Meet & Eat”. Pictures © Wiley-VCH/VK

ChemCar Competition

At the ChemCar competition—organized by the VDI’s kjVIs, the young process engineers—students build model vehicles that use chemical reactions for propulsion and control. For the first time, mechanical or electronic switches were allowed to be used for support.

Seven teams from Germany, Poland, and Indonesia have convinced the expert jury of industry representatives with their innovative concepts and were allowed to show their ChemCars on the racetrack at the 13th ChemCar competition. The race is not about fast and far, but about precision. A distance set just before the race should be driven as accurately as possible. In addition, each vehicle must be able to transport an additional charge of up to 30 % of its own weight. This year the distance was 14.5 m and the weight 30 %.

After two exciting racing sessions, moderated by Professor Irina Smirnova, TU Hamburg, and Professor Rolf Haseneder, TU Freiberg, the teams and spectators had to wait until the conference dinner to find out which team won the competition. The team with the best results in concept, safety test, presentation, and race wins the popular ChemCar Cup and a prize money of 2,000 EUR.

This year the prize went to the team UUlm from the University of Ulm. The second and third-placed teams received 1,000 and 500 EUR prize money, respectively. These prizes went to the team LoChemotive of the PHBW Mannheim, and Alte Rostlaube of the TU Dortmund. Further teams were OKTAN from the Technical University of Lodz in Poland, NichtNur-TheoretiCAR (Non-TheoretiCAR) from the RWTH Aachen, Turbine HAW from HAW Hamburg, and SMARTTRONS from the Universitas Negeri Semarang in Indonesia.

Video 1. Impressions of the 13th ChemCar race.

Awards

DECHEMA Awards

Professor Wolfgang Arlt, Friedrich Alexander University Erlangen-Nuremberg, received the Emil Kirschbaum Medal for his “groundbreaking developments in fluid process engineering, which form the basis for numerous innovations in processes in the chemical and petrochemical industry”. Professor Wolfgang Peukert, TU Munich, received the Hans Rumpf Medal for his “pioneering work in the field of particle technology, through which mechanical process engineering has developed from the fundamental research of individual processes”.

Seven graduates were awarded the DECHEMA Student Award for their professional achievements. They received a two-year free DECHEMA membership and the invitation to two meetings organized by DECHEMA.

Figure 5. Top left to right: Professor Wolfgang Peukert receives the Hans Rumpf Medal, Professor Wolfgang Arlt receives the Emil Kirschbaum Medal from Professor Thomas Hirth, Chairman of ProcessNet and Vice President for Innovation and International Affairs of KIT, Karlsruhe, Germany.

Bottom: Awardees of the DECHEMA Student Award with Dr. Michael Wilk, Chair of the ProcessNet section of Education and Innovation from Merck KGaA, Darmstadt, Germany, and Professor Kurt Wagemann, Executive Director of DECHEMA. Pictures © DECHEMA

VDI-GVC Awards

Professor Peter Stephan, TU Darmstadt, received the Golden VDI Medal of Honor in recognition of his services in process engineering and thermodynamics. In particular, the VDI acknowledged his commitment to the further development of the VDI Wärematlas (VDI Heat Atlas), the standard work of heat transfer. Dr. Christoph Held, TU Dortmund, received the Arnold-Eucken Award for his outstanding achievements in bioreactor technology and biothermodynamics. The VDI-GVC awards the prize every two years for the promotion of young engineers from industry and university institutes. The prize is endowed with 5,000 EUR.

Figure 6. Left to right: Dr. Ljuba A. Woppowa, CEO of the VDI-GVC, Professor Peter Stephan, TU Darmstadt, Dr.-Ing. Claas-Jürgen Klasen, Chairman of the VDI-GVC from Evonik Degussa, and Dr. Christoph Held, TU Dortmund. Pictures ©: Wiley-VCH/WSieß

The next ProcessNet meeting and the 34th DECHEMA Annual Meeting of Biotechnologists will be held in Aachen, Germany, from September 21 to 24, 2020.

- Event: ProcessNet-Jahrestagung and 33. DECHEMA-Jahrestagung der Biotechnologen 2018

September 2018, Aachen, Germany

Also of Interest

- Introducing the kjVIs!,

ChemViews Mag. 2010.

https://doi.org/10.1002/chemv.201000040

Young professionals in process engineering – Serving the pipeline from school to industry - Glanz- und Höhepunkte in Aachen,

Wolfgang Sieß,

CITplus 2018, 10, 9–11.

References

[1] Silke C. Wenzel, Rolf Müller Book, Host Organisms: Myxobacterium, Chapter 12, in Industrial Biotechnology: Microorganisms (Eds: Christoph Wittmann, James C. Liao), Vol 1, Wiley-VCH, Weinheim, Germany, 2016. https://doi.org/10.1002/9783527807796.ch12

[2] Norbert Kockmann, Lukas Bittorf, Waldemar Krieger, Felix Reichmann, Mira Schmalenberg, Sebastian Soboll, Smart Equipment – A Perspective Paper, Chem. Ing. Tech. 2018. https://doi.org/10.1002/cite.201800020