Micro fuel cells (MFC) have been identified as promising alternative power sources for portable electronics. Current MFC fabrication technologies rely on complex micromachining of materials such as silicon, stainless steel, and ceramics. The challenge remains to identify effective low-cost materials and fabrication methods.

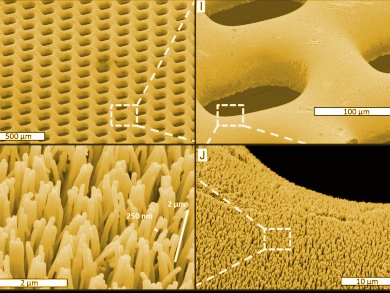

André D. Taylor, Yale University, USA, and colleagues have demonstrated the feasibility of economic fabrication of MFCs using bulk metallic glass (BMG). BMGs are metal alloys with disordered atomic structure, like that of glass, rather than the highly ordered, crystalline structure common to metals. The plastic-like processing ability of BMG allowed it to be molded or embossed into a vast range of complex shapes by thermoplastic forming (TPF). For example, the team used TPF to fabricate the hierarchical architecture of the porous supported Pt-BMG nanowire catalytic layer (pictured). TPF-based embossing of Zr-BMG was used to create flow field channels with high precision and well-defined corners and walls.

This plastic-like property of BMG is unique amongst metals due to BMGs’ viscous softening above the glass transition.

Such TPF-based techniques can be carried out in parallel in short time frames, which permits a fast and inexpensive manufacturing process that could also find applications in the fields of micro fluidics, heterogeneous catalysis, sensors, and other electrochemical systems.

- Bulk Metallic Glass Micro Fuel Cell,

Ryan C. Sekol, Golden Kumar, Marcelo Carmo, Forrest Gittleson, Nathan Hardesty-Dyck, Sundeep Mukherjee, Jan Schroers, André D. Taylor,

Small 2012.

DOI: 10.1002/smll.201201647