Rigid polyurethane (PU) foams play a major role in saving energy costs when used as insulating panels in construction or in items such as refrigerators. Flexible foams are employed as cushioning for a variety of products, including in furniture and packaging. These low-cost materials have been used for decades. However, they are facing regulation changes that restrict the use of toxic isocyanates, as well as isocyanate supply problems. In addition, PU foams can be difficult to recycle.

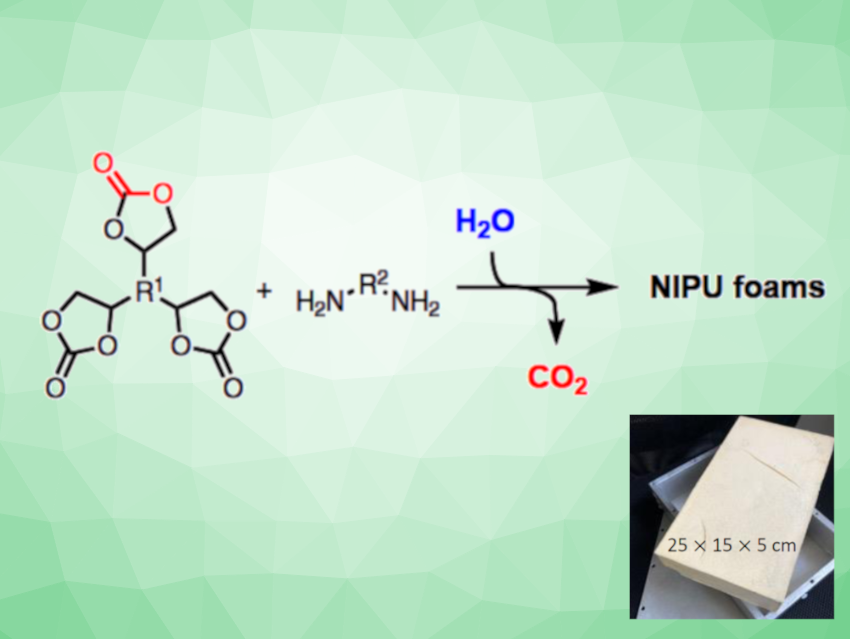

Christophe Detrembleur and colleagues, University of Liege, Belgium, have developed a simple process for preparing polyurethane foams that are isocyanate-free and recyclable. In the presence of a catalytic base, a range of five-membered cyclic carbonates were hydrolyzed by water in a temperature range of 80–100 °C, resulting in the release of carbon dioxide. This in-situ-formed gas can be used as a “blowing agent” in solvent-free poly(hydroxyurethane) (PHU) formulations composed of a tris(cyclic carbonate) and a diamine (example reaction pictured), where it induces foaming and the generation of polymer with a regular cellular network.

The technique is robust, can be scaled up, and it is compatible with existing industrial foaming infrastructure. It could have potential for the next generation of more sustainable and recyclable foams adapted to the demands of many sectors, according to the researchers.

- Water‐Induced Self‐Blown Non‐Isocyanate Polyurethane Foams,

Maxime Bourguignon, Bruno Grignard, Christophe Detrembleur,

Angew. Chem. Int. Ed. 2022.

https://doi.org/10.1002/anie.202213422

is it patented or commercially available?

We indeed patented the technology. Most of the starting products are commercially available.

Best regards