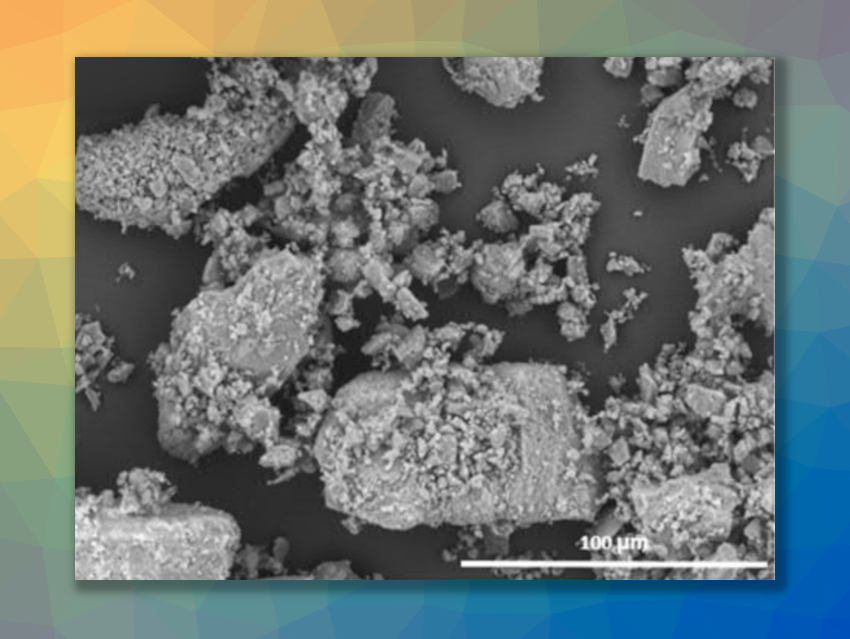

Aluminum oxide can serve as a catalyst or a catalyst support in different applications—for example, the dehydration of methanol to dimethyl ether. Often, the gamma polymorph (γ-Al2O3) of alumina is chosen due to its relatively high surface area. However, γ-Al2O3 is susceptible to chemical weathering in the presence of water, leading to the formation of boehmite (γ-AlOOH), which diminishes its activity and stability over time. Corundum (α-Al2O3) is thermally stable and hydrothermally very robust, but typically has a low surface area. However, α-Al2O3 with a high surface area can be produced via a mechanochemical route using ball milling.

Ferdi Schüth, Max Planck Institute for Coal Research, Mülheim an der Ruhr, Germany, and colleagues have investigated alumina polymorphs prepared by thermal and mechanochemical methods as catalysts for the dehydration of methanol to produce dimethyl ether. The team used alumina samples with different crystalline phases, including γ-, θ, δ-, and α-Al2O3. The activity and stability of the catalysts were studied in a fixed-bed continuous-flow reactor setup.

The team found correlations of the performance with the surface area, the total number of acidic sites, and the crystalline phase of the alumina catalysts. Ball-milling-derived α-Al2O3 demonstrated high activity, selectivity, and exceptional stability. The researchers attribute this to its robustness against active site poisoning by the by-product water, combined with its high surface area. Based on the results, they point out that exploring the activity of high-surface-area α-alumina in other reactions that are typically performed over γ-alumina could be interesting.

- Methanol Dehydration to Dimethyl Ether on Ball Milling‐Derived High‐Surface‐Area Alpha‐Alumina Catalysts,

Özgül Agbaba, Amol P. Amrute, Sarah Triller, Ferdi Schüth, Cristina Ochoa-Hernandez,

ChemCatChem 2023.

https://doi.org/10.1002/cctc.202301159